I wanted to seal several PCBs from not just water and general contamination, but from stopping the solder being a problem to anyone as I had needed to use solder that contained lead for these.

I searched for "conformal" coating and read the reviews - This seemed an excellent choice and yet again, the reviews saved me so much time and wasted money as it works perfectly. Yes there is a strong solvent smell and it is highly inflammable as it dries out, but that is normal with all conformal coatings and cannot be avoided as it needs fairly aggressive solvents to dissolve the plastic the coating is actually made of.

The real test is durability, even with a single light coat, the boards have all come out perfect, with no problems I could see, even using x30 magnification on the PCBs.

I don't know how it compares to other brands price-wise, but does it matter? One single vulnerable PCB will cost you a lot more than you could ever save (unless you are running a production line)! I am staying with CRC now as it has been better than other brands I have used before.

I had a couple of battery chargers that sometimes get caught in the rain while charging my boat batteries. I am familiar with other moisture protection sprays. This one was less expensive that the brands I was familiar with. I assume that the company that makes this product is conscientious enough to not sell me a less that adequate spray.coating.

Only time will tell.

It is a four until I know better.

This stuff Works great! I mill my prototype circuit boards out on my CNC mill and for testing purposes I usually don't need to worry about any sort of coating or weather resistance.

Well I needed a way to make some of my circuit boards water resistant for testing outdoors (these control a series of solar panels)

and this did the trick, I sprayed a couple layers on each board, It goes on thick and seals up around the larger components.

I tested it by powering one of them on and dunking it under water. It continued to function properly and I am very pleased with it.

I had to replace a MOSFET on a generator and the board was originally coated due to being outside. I purchased this to touch up the board after repairs. I applied a few coats to build it to the same thickness as the original coating. It sprayed well even though I was working outdoors in high humidity. The end coating was crystal clear and seems very durable.

Electronic safe. I used this for waterproofing my done Controller board. Covered my PCB following several lite applications waiting ~ 5 minutes between dustings. (Following the instructions). After 3-4 dustings, I went a bit heavier for the final 2 seal coats. I followed up with plastic coat, but probably did not need the plastic coat.

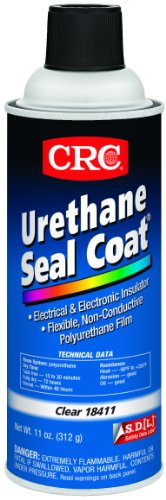

Feature Product

- High dielectric strength 1300 volts/mil, high surface and volume resistivity make it ideal for electrical/electronics applications

- Effective temperature range of -90 to 250 degrees F

- Dries quickly to a hard, durable, flexible and non-conductive film

- Abrasion resistant insulator for electrical and electronic equipment and components

- Allows easy visualization of circuit paths on PC boards

Description

CRC urethane seal coat - red provides a conformal polyurethane coating that insulates electrical equipment and seals out water and moisture. This product's red coloration allows easy visualization and confidentiality. It dries quickly to a hard, durable and flexible film. Recommended for use on motor windings, terminals, bus bars, commutator ends, stator coils, and PC boards. Wide temperature range - effective from -90 to 250 degrees F. Abrasion resistant - ensures lasting protection. High dielectric strength of 2000 volts/mil. Ideal for electrical/electronics applications. Material safety data label - provides instant access to current safety information should an accident or OSHA inspection occur. Helps comply with OSHA Hazard Communications Standard 29 CFR 1910.1200. 141 degrees F boiling point.

It seals electrical things shut to be sure. I also use it on my vehicle battery terminals after cleaning them, to seal against corrosion. Most excellent product !

Works well for coating PWB's to protect them from moisture and corrosion. Have coated 40+ pwb's with 1 can so far and still have lot's to go.

Leaves a nice quick drying coating.

Cons:

- smells awful. I always go outside for using it, and need to leave the item with a fresh coating outside for a few minutes before taking it back in.

Completely waterproofed my project! Easy to use and apply, quick drying time.

Only con I can think of is the smell. Make sure you are in a very well ventilated area when you let this cure.

Sprayed a raspberry pi that I have in an enclosure outside. It's quite wet here in WA state and it's been running just fine so far.

0 Komentar